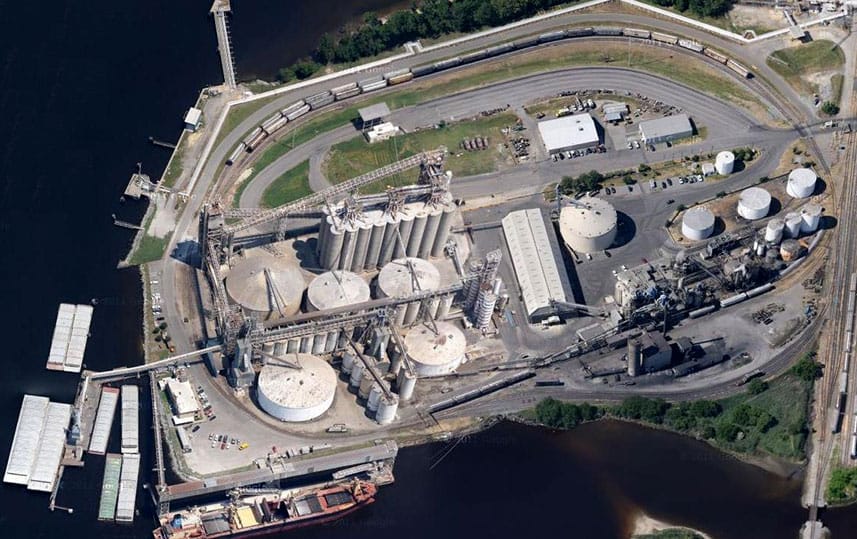

Perdue Agribusiness

Chesapeake, Virginia

McPherson Design Group has completed approximately 30 projects for Perdue Agribusiness since 2012. These projects have ranged from inspections to repairs and new construction. We have completed projects at many Perdue locations across Virginia, North Carolina, Maryland and Deleware. Some examples of these projects are as follows:

Conveyor 252 Assessment and Repairs

This project included directing an underwater dive team in the inspection of the marine facilities. MDG provided a condition assessment, development of the repair drawings and specifications, a final report, repair recommendations and a cost estimate. The project involved the inspection of a grain conveyor support system, including transfer stations, 500 feet of steel truss structures, 100-foot-tall steel tower, concrete wharf and miscellaneous marine structures built over the Elizabeth River.

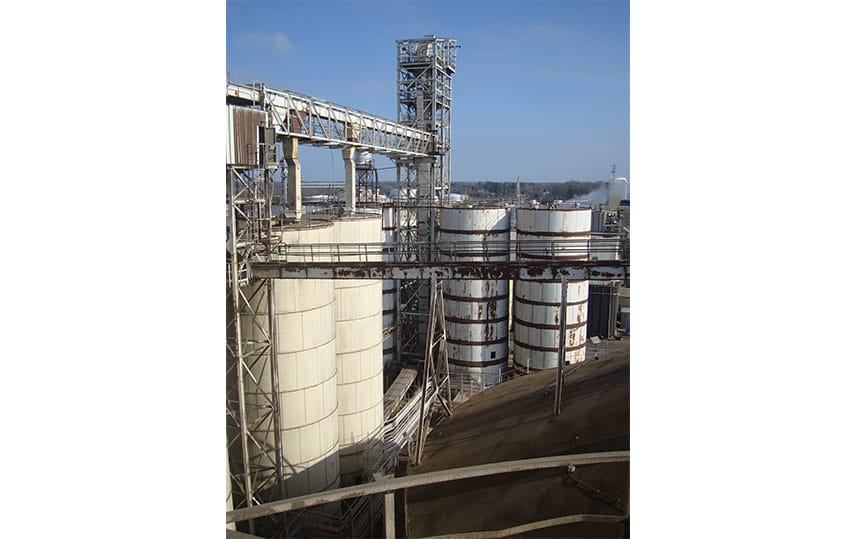

Plant Repairs

This project included providing construction documents for repairs that were recommended in our condition assessment report. The repairs were for three (3) existing structures: 1) Receiving Tower Structure; 2) Tower One Structure; and 3) Conveyor Support Structure. Our services were divided into three parts: 1) additional field survey for measuring the geometry structure, 2) preparation of construction drawings, and 3) construction administration services.

Hopper Popper Support Framing

This project included providing design drawings and specifications for the installation of an overhead frame to support the “Hopper-Popper” in the existing rail unloading building at the Perdue Chesapeake Facility. We provided field investigation to support the design work while not interfering with Plant operations. We also coordinated our design work with the Hopper-Popper Manufacturer, Pneumatic Systems of Mankato, MN, and with the local Perdue representatives for rail operations. We also provided shop drawing review and construction administration services for this project.

Ship Loader Repairs

McPherson Design Group conducted a condition assessment and prepared repair documents for a ship loader located at the Perdue Chesapeake Plant on the Elizabeth River. The ship loader is one of two at the facility and was constructed by the Products Engineering Company of Seattle, Washington in 1975. The ship loader has a counterweighted boom roughly 115 feet in length and is supported roughly 40 feet above a concrete pier on a rail mounted pedestal. An overhead truss supports conveyors which deliver product to the ship loader. The ship loader is used by the Owner to load bulk agricultural products on freighters for overseas export. The ship loader had deteriorated from lack of maintenance and been repeatedly damaged without repair. In 2013, McPherson Design Group was retained to evaluate the safety of the facility and subsequently to provide repair documents. McPherson Design Group provided construction administration services for this project as well.